Silicone Free Thermal Pad: CPVP-F Series

Soft, 2W/m•K silicone-free putty-thermal pad.

Properties

| Property | Test Method | CPVP-F |

|---|---|---|

| Thickness | – | 1.0, 2.0, 3.0, 4.0, 5.0, 6.0 |

| Standard Sheet Size | – | 210 x 510 |

| Thermal Conductivity (W/m・K) | JIS R 2616 Hot wire method |

2.0 |

| ISO 22007-2 Hot-disc method |

1.4 | |

| Hardness (ASKER C) | JIS K 7312 | 0 (putty layer) |

| Volume Resistivity (Ω・cm) | JIS K 6911 | 1.0 X 10¹¹ |

| Flame Resistance | UL94 | V-0 |

| Operating Temperature (°C) | – | -40 ~ 125 |

| Color | – | Dark Green / White |

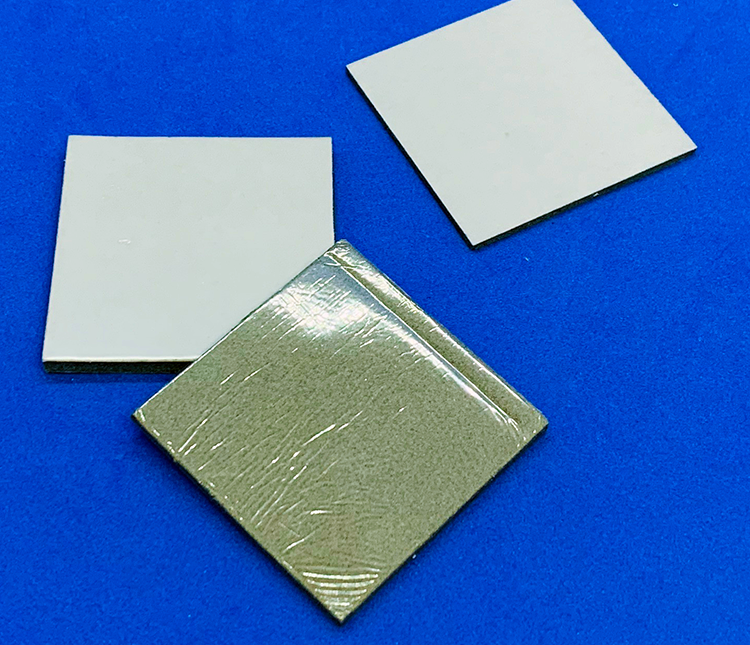

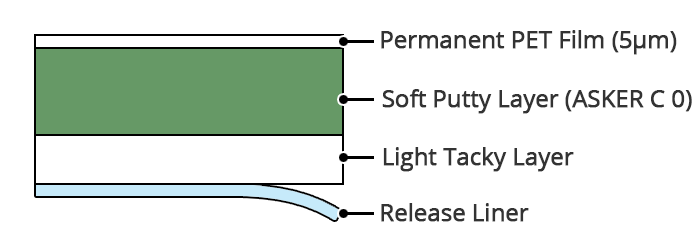

Structure

Super compliable (ASKER C 0) material sandwiched between thin permanent PET film and light tacky layer for easy handling. Thin permanent PET film provides mechanical strength and prevents dust and debris from getting trapped on the putty surface.

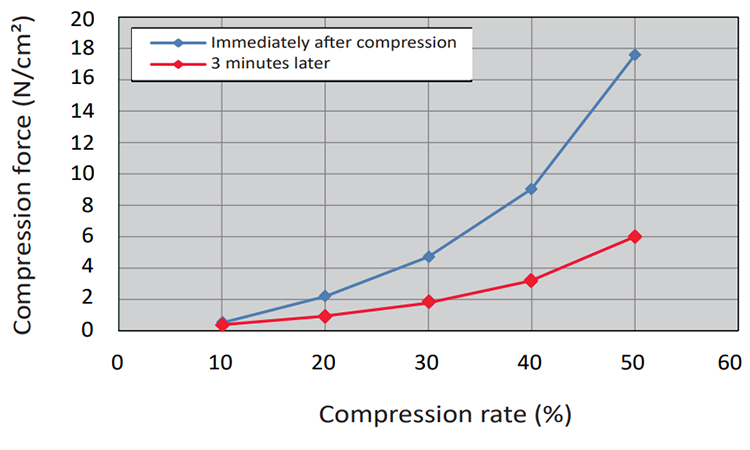

Compression Force Test And Stress Relaxation (after 3 min)

Test Condition

Test Results

| Compression rate (%) | 10% | 20% | 30% | 40% | 50% |

|---|---|---|---|---|---|

| Compression force (N) | 0.5 | 1.7 | 3.8 | 7.6 | 15.6 |

| Stress relaxation (N) | 0.1 | 0.4 | 1.1 | 2.1 | 4.1 |

Comparison between Compression test vs Stress relaxation test

Compression test data shows the amount of applied force (N) at the moment the test sample is compressed. Stress relaxation data uses the same test set up as the compression test, but the data is taken after a certain amount of time has passed (such as three minutes). With our soft and compliable materials, the amount of force tends to ease over time. In the long-term, it is more accurate to consider the data from the stress relaxation test since the force is much less than initial compression force. However, in some cases where there are delicate components that can only accept up to a specified amount of force, the peak compression force from our compression test should be considered.

* Specifications and dimensions are subject to change without notice for product improvement.