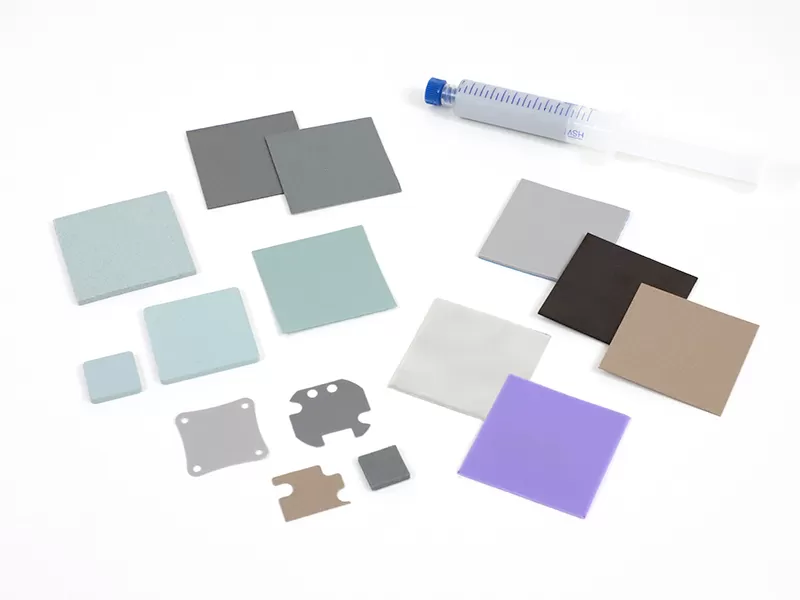

Thermal Pads & Thermal Interface Materials

Even as technology advances to high performance and compact designs, engineers are constantly challenged to innovate creative ways to manage heat. An application’s thermal management can be crucial in increasing its life expectancy and brand reliability.

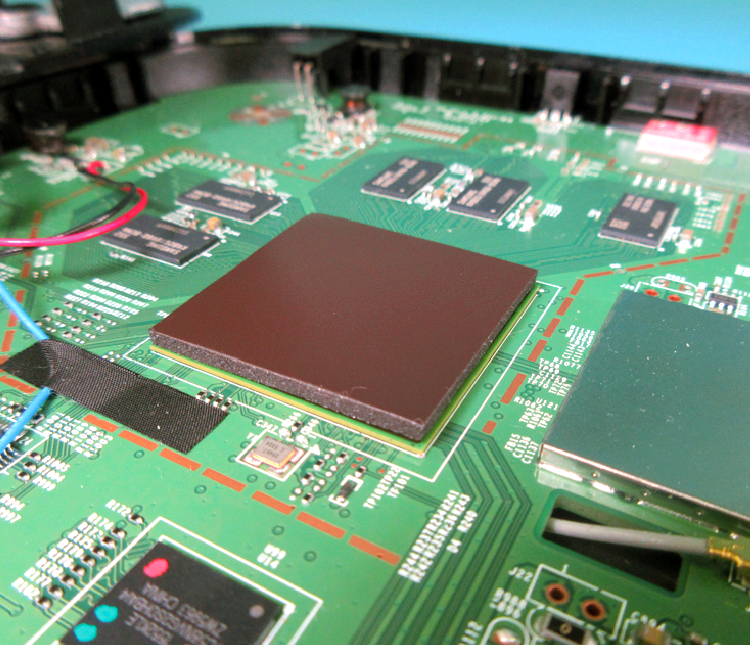

Thermal Interface Materials (TIMS) are placed between the heat source (such as a microprocessor) to a heat sink or heat spreader. Filling the air gap with a pad or putty allows for an efficient transfer of heat away from the heat source to maintain its performance. Considering the thermal conductivity of air is about 0.02W/m*K (which tends to insulate heat), applying even a low thermal conductivity 1.5 W/m*K thermal pad can dramatically change the junction temperature of the heat source.

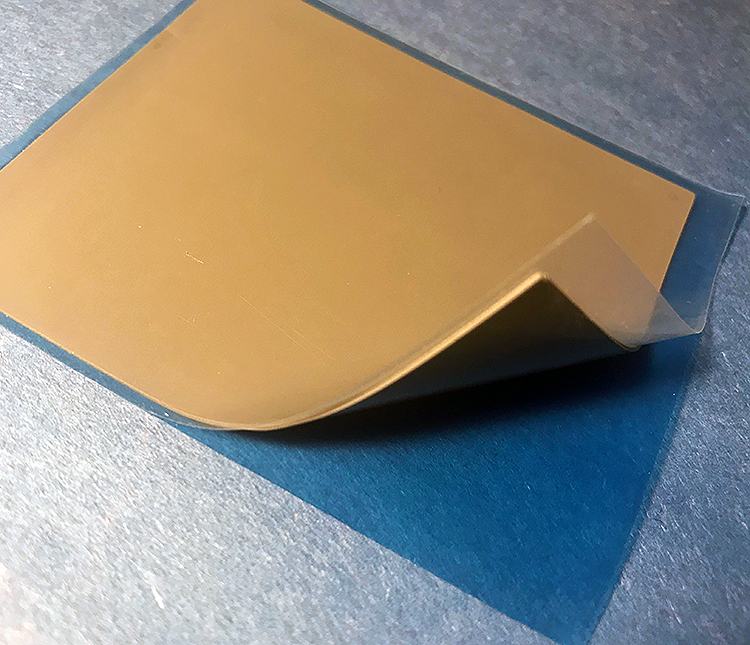

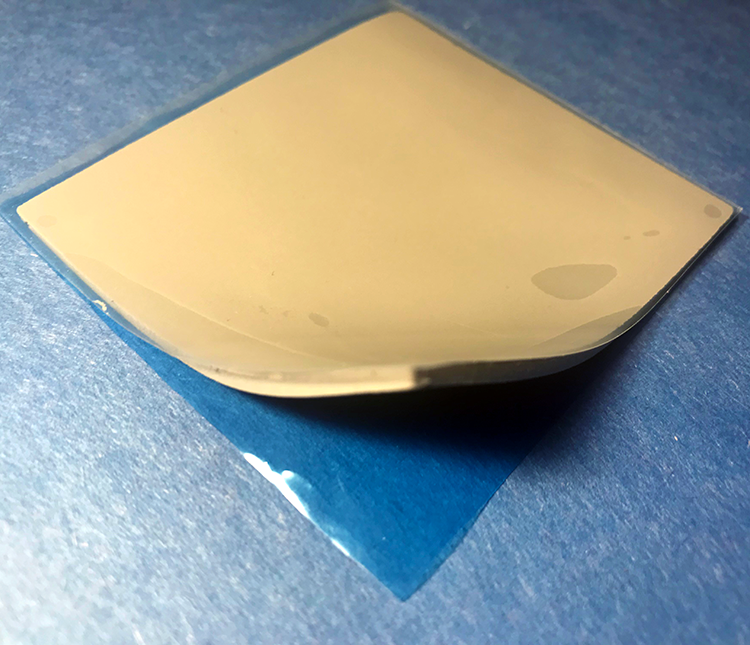

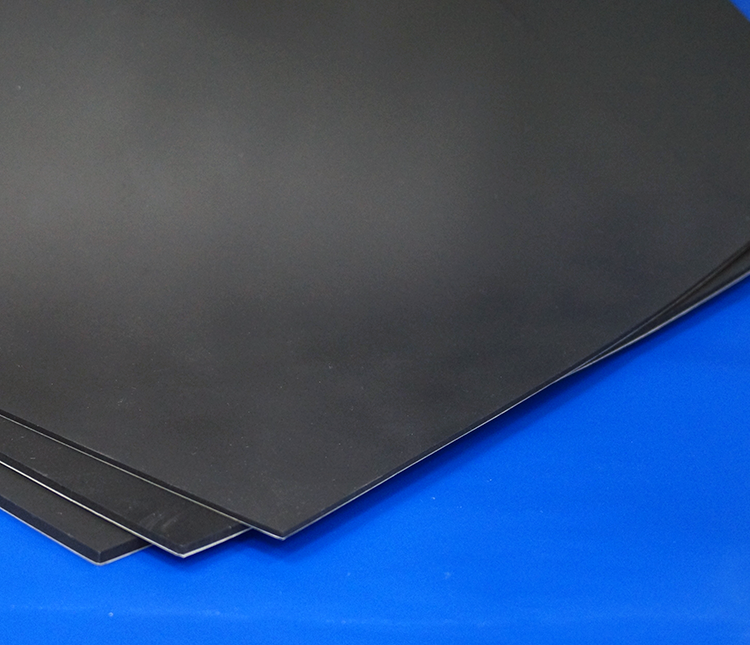

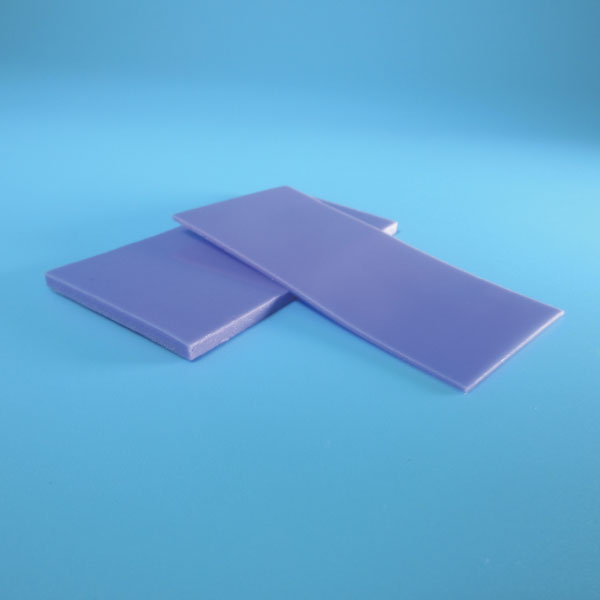

Silicone-Base Thermal Pads

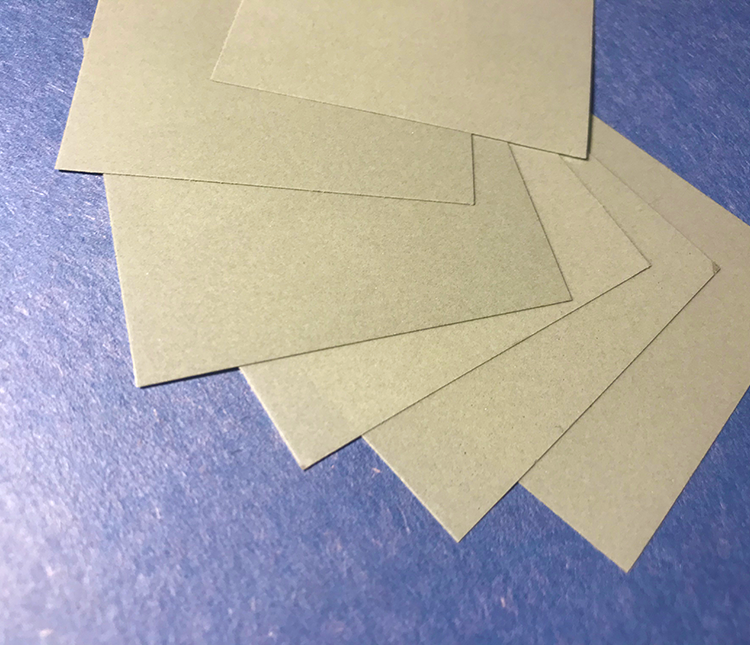

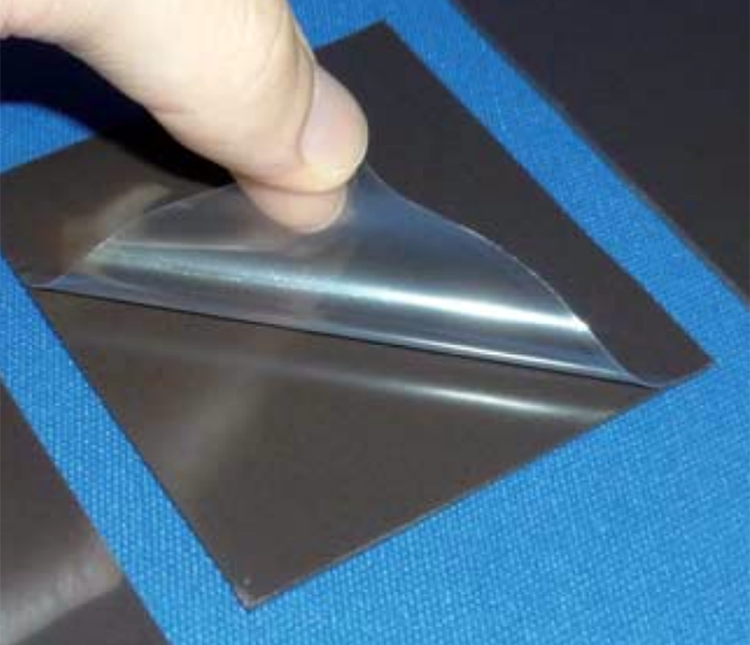

Our IMTH series silicone-based thermal pads are one of our TIM (Thermal Interface Materials) which are one of our most popular thermal management components. They are designed to withstand high temperatures (up to 200°C) and has very low outgassing compared to similar silicone-based TIM’s. KITAGAWA INDUSTRIES America offers a wide variety from 1.5 W/m*K up to 7.0 W/m*K. Our standard product is inherently tacky on both sides. We also offer options such as one-side less tacky, fiberglass reinforced and lower durometer versions.

IMTH15 Series thermal pads have a high conductivity of 1.5 W/m*K and is available in 0.3 mm to 25 mm thicknesses. They are also cost effective thermal management solutions.

MTH30 series thermal pads have a high conductivity of 3.0 W/m*K and is available in 0.3 mm to 10 mm thicknesses. They are also cost effective thermal management solutions.

IMTH50 series thermal pads have a high conductivity of 5.0 W/m*K and is available in 0.5 mm to 10 mm thicknesses. They are also the superior and longer lasting solutions in comparison to thermal grease.

IMTH70 series thermal pads have a high conductivity of 7.0 W/m*K and is available in 0.5 mm to 10 mm thicknesses. They are also the superior and longer lasting solutions in comparison to thermal grease.

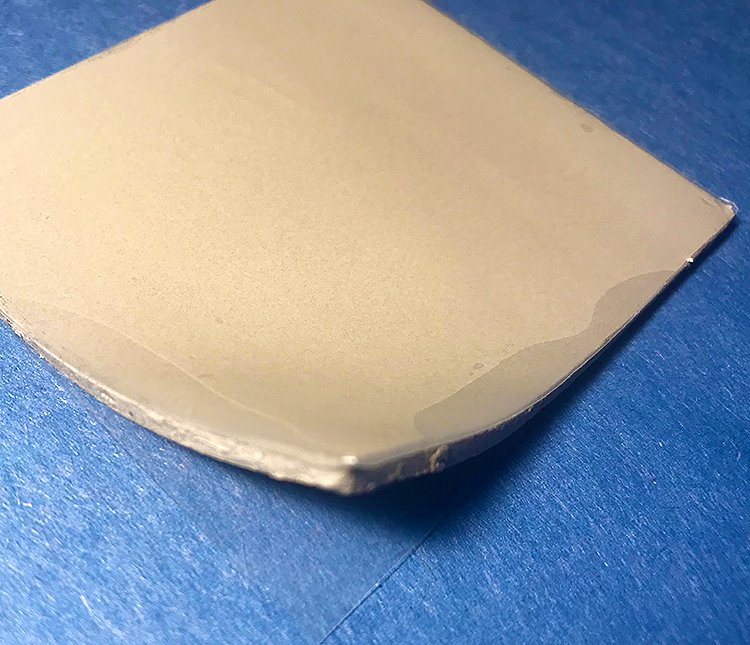

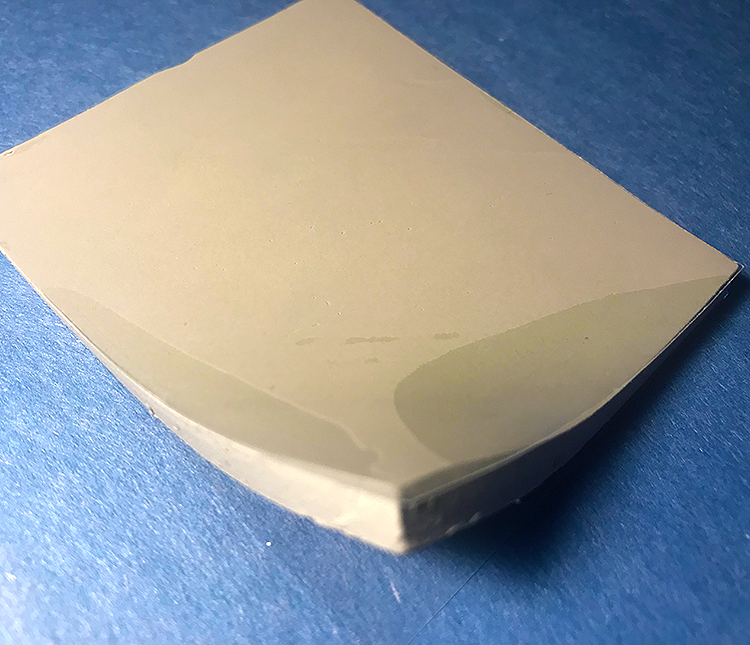

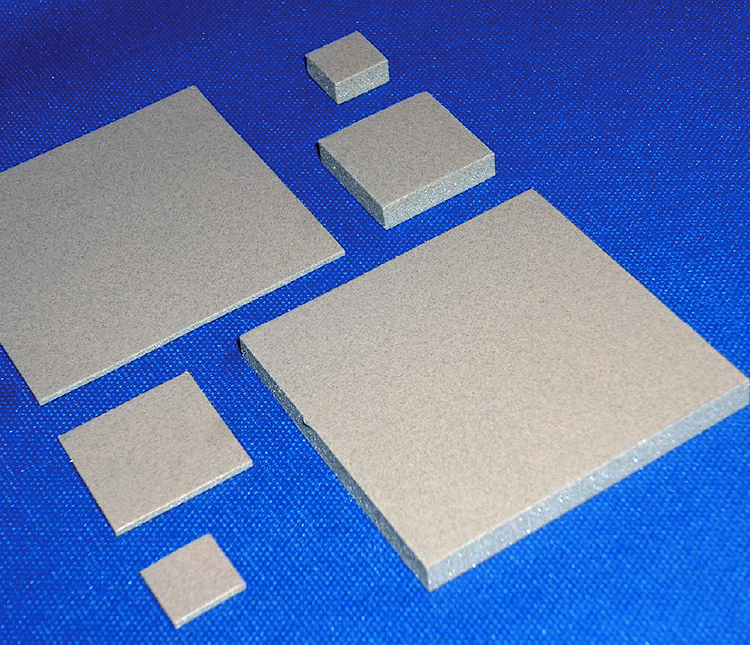

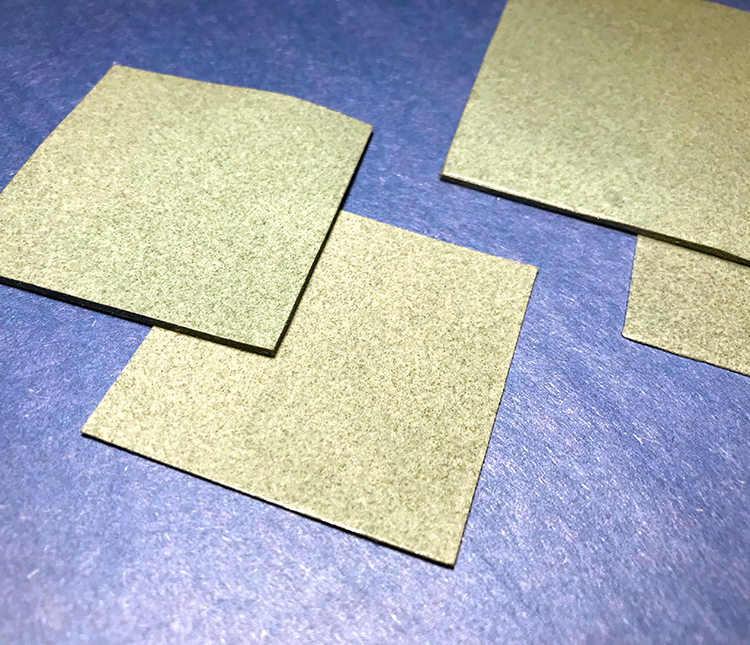

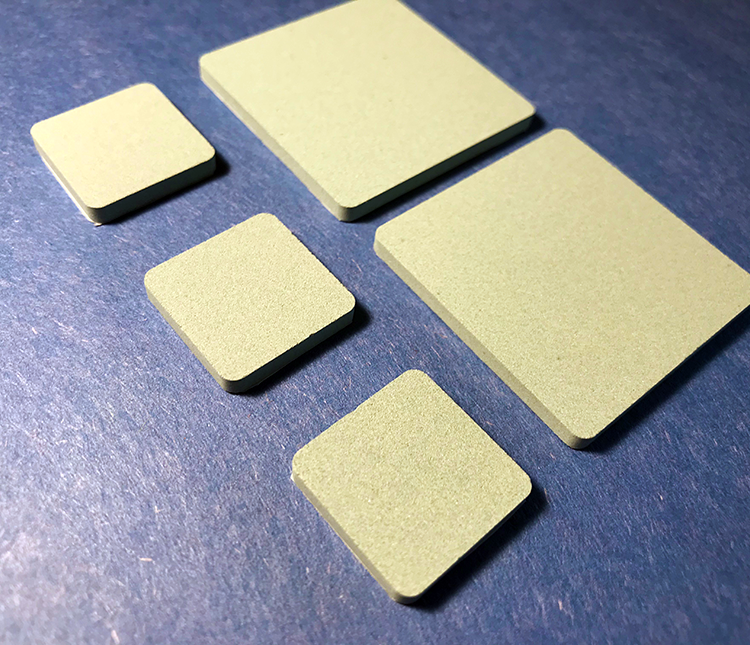

Silicone-Free Thermal Pads

Many applications today such as optical, medical, and sensor devices certain requirements preventing them from using silicone based products. To meet these demands, KITAGAWA INDUSTRIES America offers a variety of silicone-free thermal pads. We use an acrylic rubber base to eliminate any concerns of siloxane outgassing and oil-bleeding. Our silicone-free thermal pads are very soft which is beneficial for reducing applied stress on the PCB and lowering the thermal resistance.

Silicone-Free, heat-conductive vibration damping sheet. Silicone-free material, so there is no siloxane outgassing. Suitable for applications with both thermal and vibration/shock issues.

Soft, 5W/m•K silicone-free thermal pad for high operating temperature applications. Compliable thermal pad helps to crowd out air bubbles to reduce thermal resistance.

Super soft and compliable material allows for less pressure on the heat source, such as the IC or PCB, when compared to a standard TIM. Suitable for vibration control.

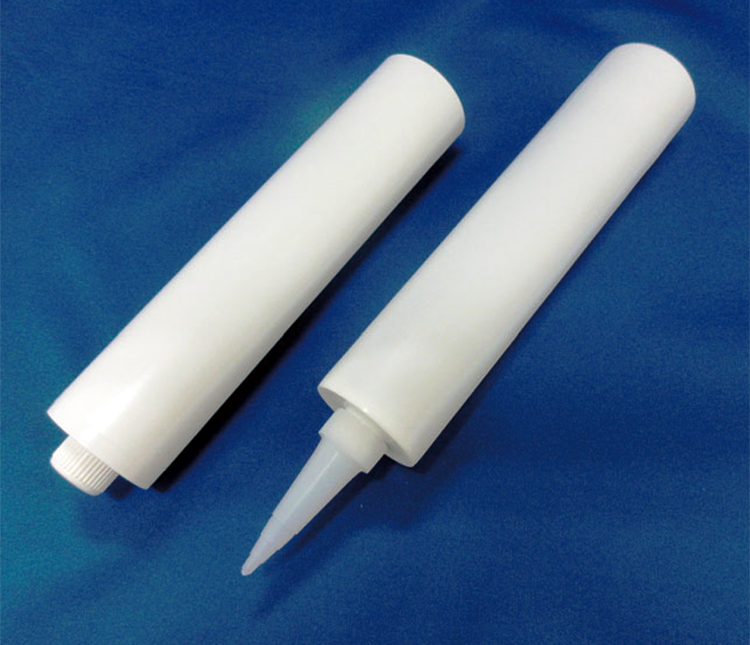

Putty does not drip even when thickly applied. Extremely useful in filling gaps with varying component heights. Very little compressive force on…

Soft, 3W/m・K silicone-free thermal pad for high operating temperature applications. One side thin permanent PET film and one side naturally tacky is…

Soft (ASKER C 18) silicone-free thermal pad. Excellent stress relaxation property reduces the stress on the elements after mounting. Overall low outgassing.

Super compliable (ASKER C 0) material sandwiched between thin permanent PET film and light tacky layer for easy handling. Because the CPVP is so soft, very little pressure is applied to components.

Ultra-thin, thermally conductive sheet, suitable for devices where clearance is limited. Available thicknesses ranging from 0.1 mm ~ 0.25 mm at every 0.05 mm pitch.

Ultra-thin, thermally conductive sheet, suitable for devices where clearance is limited. Available thicknesses ranging from 0.1 mm ~ 0.25 mm at every 0.05 mm pitch.

Silicone-free material, great for applications sensitive to siloxane and oil-bleeds. KGS-original formulation allows for great EMC noise suppression.

Low dielectric thermal pad which helps to suppress noise in the GHz band which occurs due to heatsink resonance phenomena.

Dual Functioning Thermal Pads

With an increasing number of applications dealing with more than one issue in the same location, our silicone-free dual functioning materials are a cost effective solution for resolving both problems at the same time. Some examples are our EMPV4 (Dual functioning Thermal pad and EMI Absorber) and CPAG (Dual functioning Thermal pad and Vibration Dampener). Upon special request, KITAGAWA INDUSTRIES America can also layer two or more of our silicone-free materials into one without trapping any air bubbles. Multiple layered products are fused together during manufacturing in such a way that the layers will not come apart.

Silicone-Free, heat-conductive vibration damping sheet. Silicone-free material, so there is no siloxane outgassing. Suitable for applications with both thermal and vibration/shock issues.

Silicone-free thermal interface material with EMI noise suppression. Compliable material (ASKER C 40) that conforms to uneven surfaces. High operating temperature from -40 ~ + 110 ° C.

Silicone-free material, great for applications sensitive to siloxane and oil-bleeds. KGS-original formulation allows for great EMC noise suppression.

Low dielectric thermal pad which helps to suppress noise in the GHz band which occurs due to heatsink resonance phenomena.

Special Thermal Interface Materials

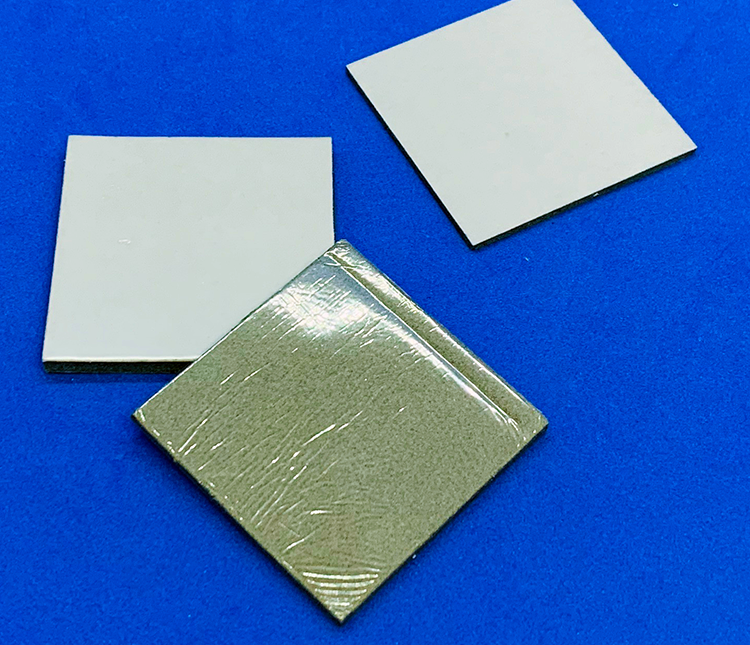

Our Special TIM (Thermal Interface Materials) include our Ceramic Heat Sink and Thermal Heat Spreader. The ceramic heat sink has a greater surface area due to its porous structure which allows for effective dissipation of heat.

Our cost effective aluminum heat spreader is a great solution for evenly distributing heat throughout, preventing a hot spot from occurring.

Compared to traditional aluminum, the combination of the larger surface area provided by the porous structure and higher levels of thermal radiation amounts to…

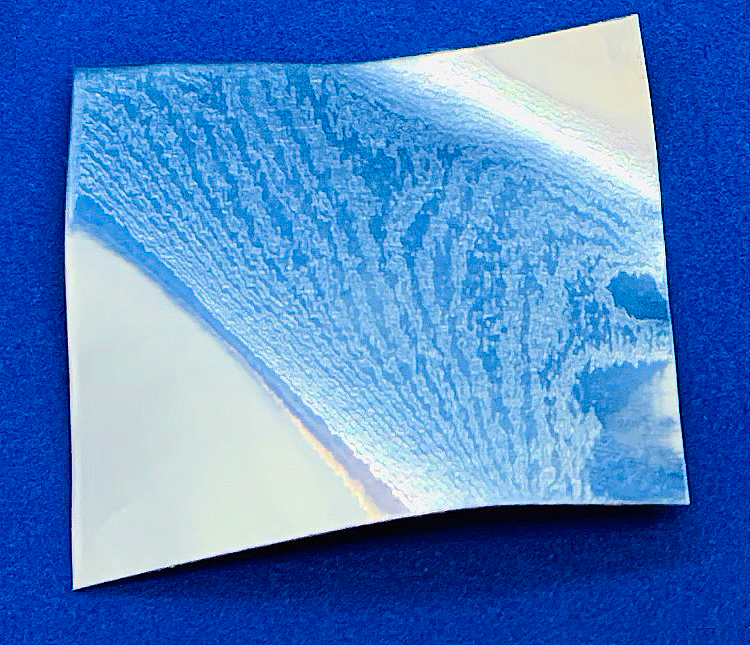

Thin and flexible heat spreading sheet for superior thermal management. Aluminum heat spreader material with excellent thermal conductivity…

Putty does not drip even when thickly applied. Extremely useful in filling gaps with varying component heights. Very little compressive force on…

Low dielectric thermal pad which helps to suppress noise in the GHz band which occurs due to heatsink resonance phenomena.

Graphite-hybrid sheet for reducing hot spots and reducing heat reflection to the original heat source