On-Board Grounding Contacts (SMT-type)

KITAGAWA INDUSTRIES America offers a wide variety of board-level mounting (SMT) grounding contacts as well as specialized SMT clasps for small cables and shielding-can clips. Our simple yet sophisticated on-board contacts all use SMT (surface mount technology). Some benefits include:

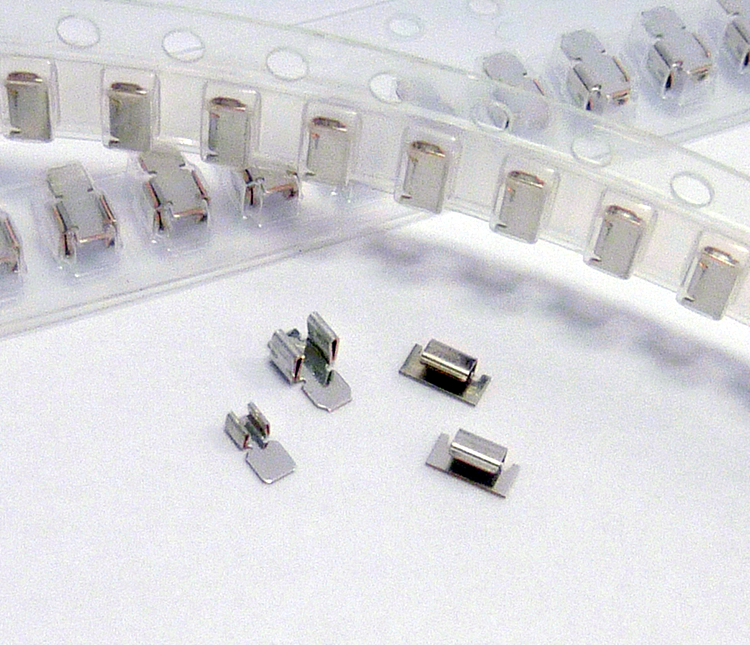

KITAGAWA INDUSTRIES America carries a large selection of onboard contacts (OG) that are excellent grounding materials for reducing EMI noise at the board level.

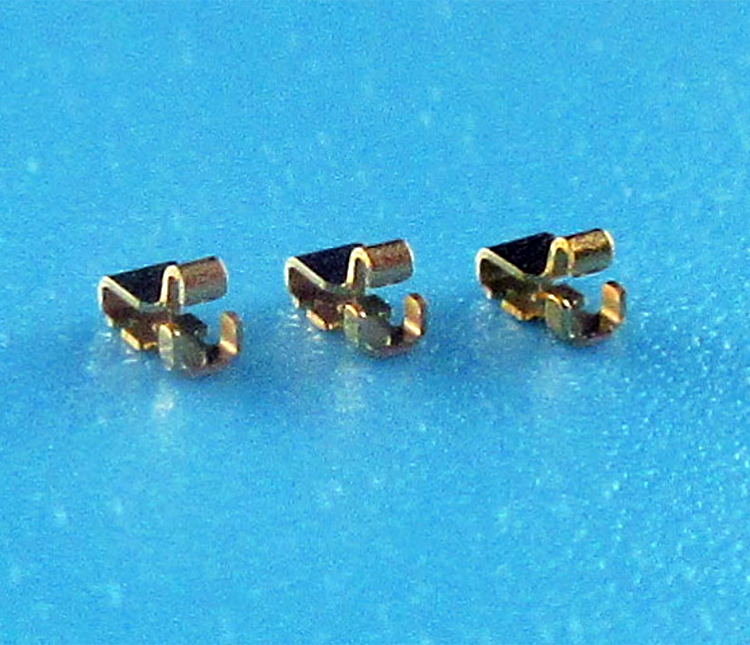

Tiny profile, board-level EMC grounding component. Compact design, great for space-conscious applications (such as smart, wearable devices).

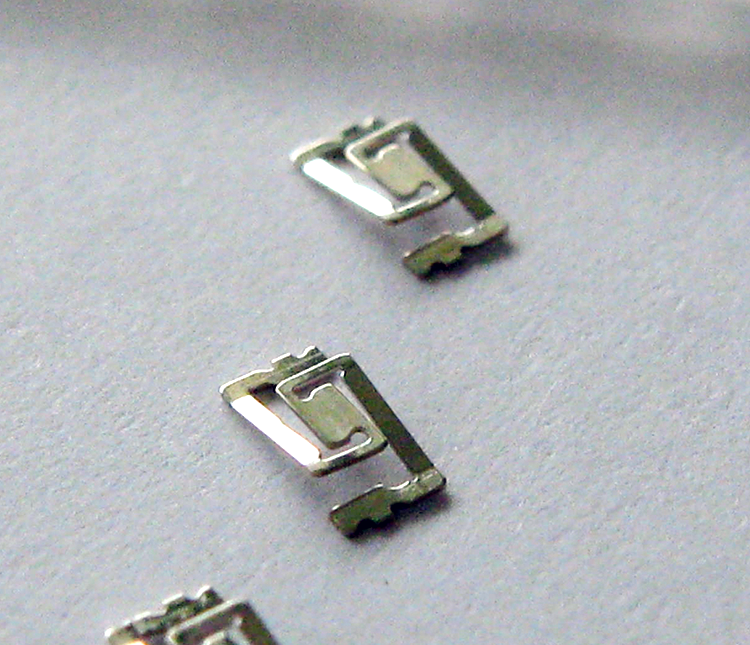

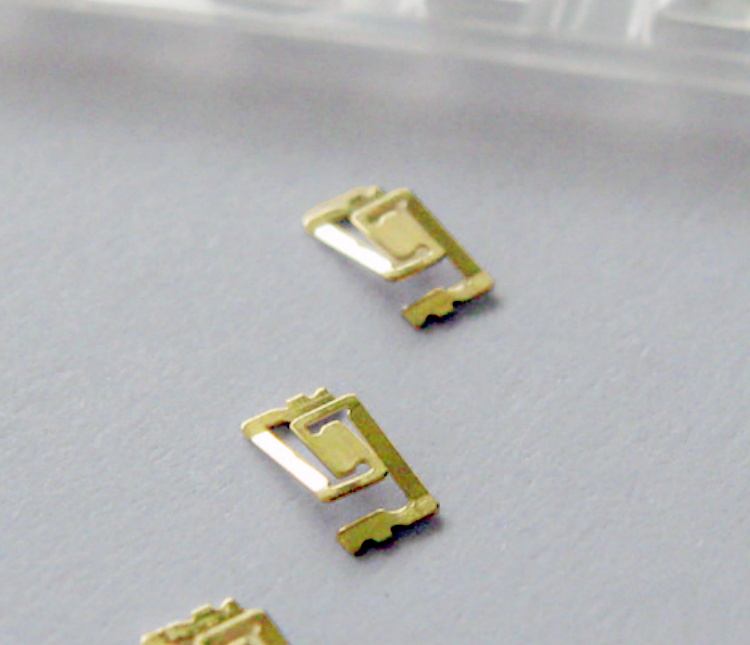

On-board grounding component designed for small gaps. Low profile contact designed for space conscious applications.

On-board grounding component designed for small gaps. Low profile contact designed for space conscious applications.

Connecting a GND layer of PCB with multiple points on a chassis can be expected to suppress radiation noise. Can be used under high temperature at 150ºC.

SMT grounding contact for engine compartment PCB. Spring mechanism capable of withstanding 10 million deflections caused by engine vibration.

SMT-type EMC grounding contact for PCB’s in engine compartments. Unique dimple design allows for continued eletrical contact.

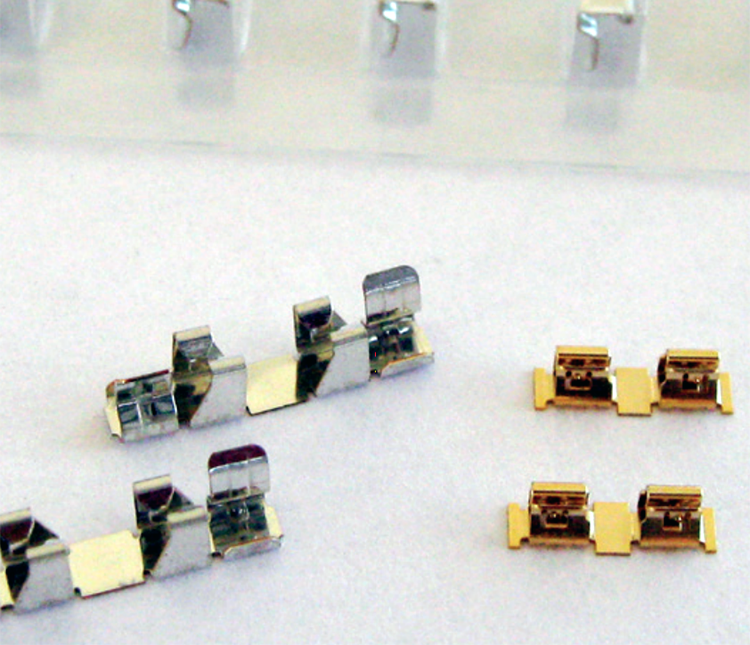

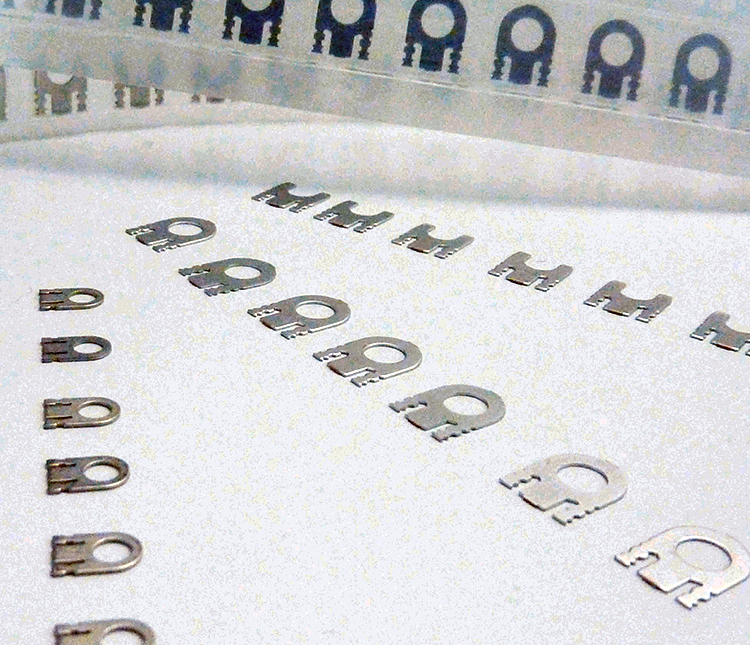

Compact cables clamps applicable to automated mounting on PC board. Board‐level wire management clamps. Available in side or top insertion.

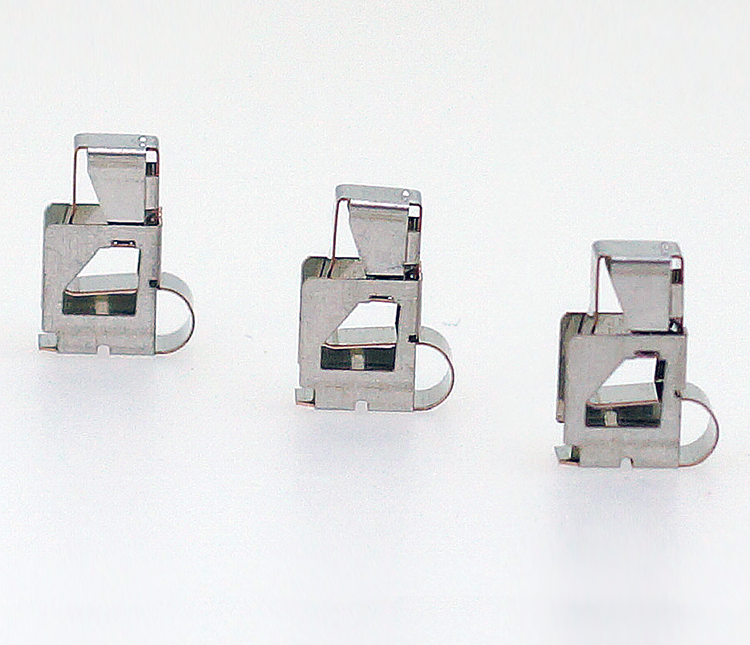

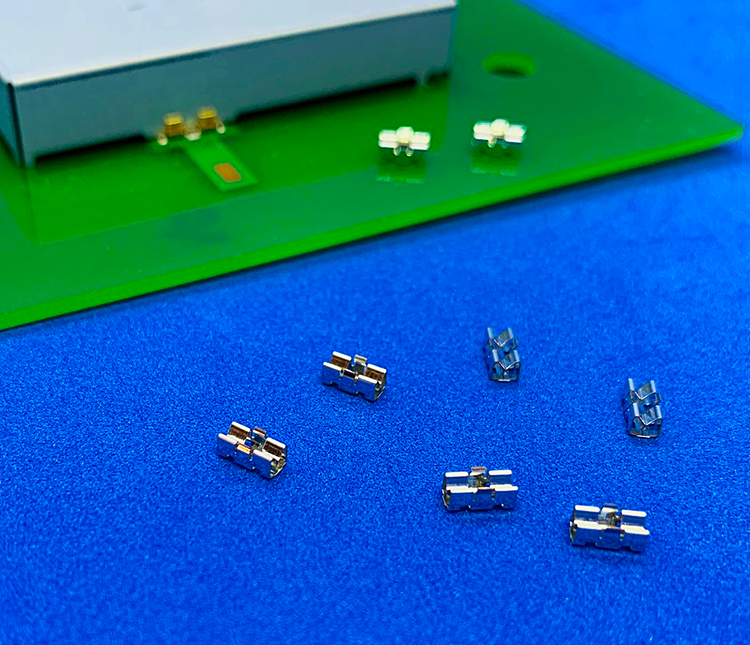

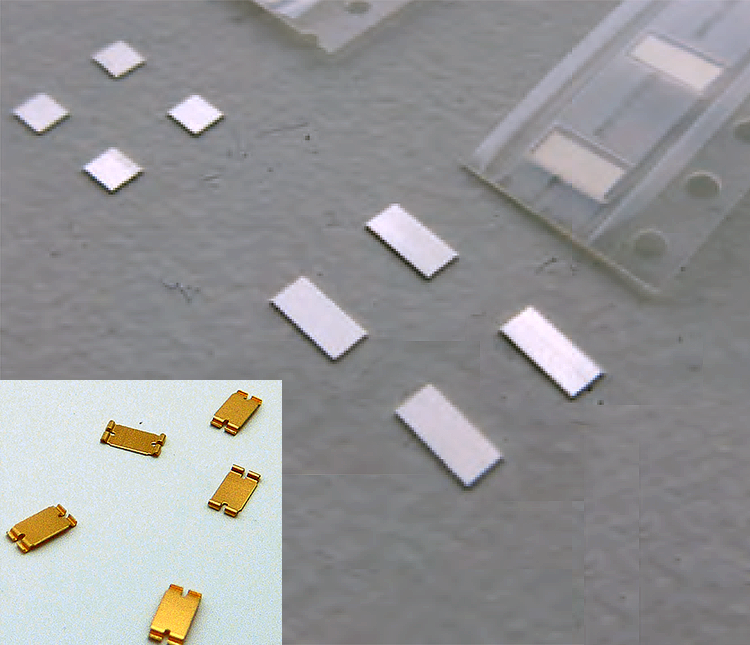

These are unique onboard contacts that act as both shielding can holders and rounding components. It can be snapped into the clips and taken off when needed.

Automated mounting applicable fixture “On-Board Clip” for shielding can. Multi-point GND is provided to shielding can and reinforced shielding performance.

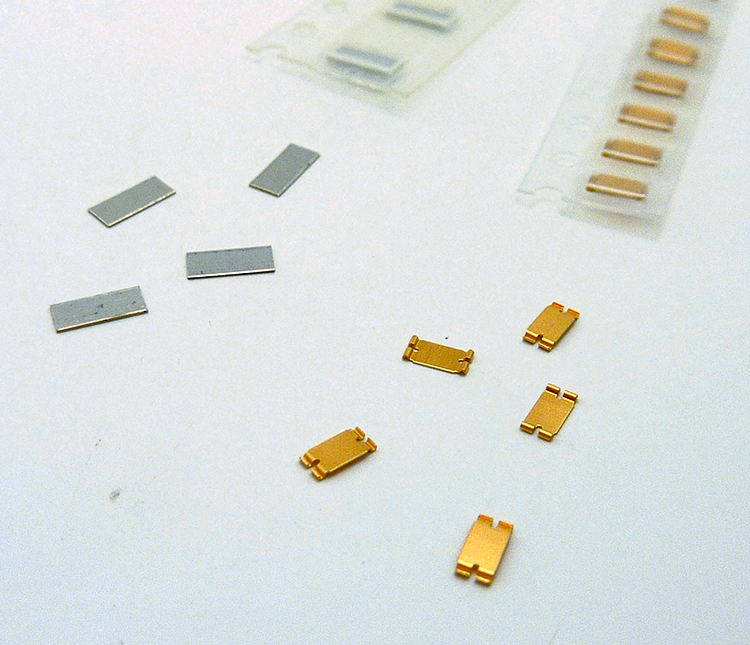

Eliminates problems with bad contact due to soldering flux. Ensures reliable, stable electrical contact for EMC grounding.

OGP solves contact failure problems caused by solder flux. Eliminates continuity failure caused by pattern scraping between a PCB and pogo pins and a PCB and a metal plate.

Side contacts for perpendicular grounding. Ideal for applications where standard grounding between parallel boards/chassis is not possible.

Side contacts for perpendicular grounding. Due to low profile design (2mm), it’s suitable for small electronic devices. Operating temperature -40ºC ~ 150ºC.

For reliable and stable electrical grounding when applied at screw holes. Helps to prevent EMC grounding reduction from loosened screws.