EMI Grounding

EMC grounding is one of the most cost-effective ways to reduce EMI noise at the board, cable, and system levels. The most ideal EMC ground is a short and wide connection with low impedance, especially when grounding problematic frequencies above 200Mhz. Some examples include spring contacts and snap-in grounding spacers for PCBs, 360° metal clamps for cables (primarily to ground the shielding on the cable), and grounding straps for cables and enclosures.

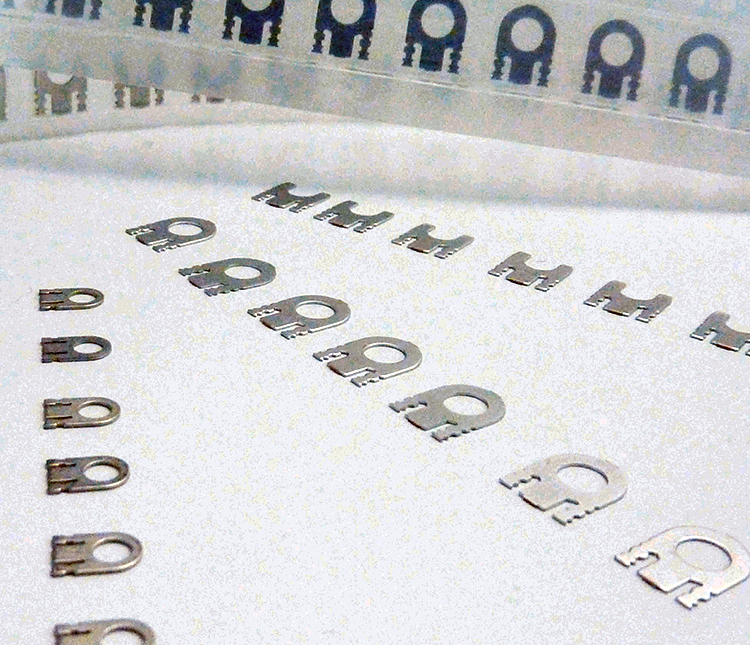

On-board Grounding Contacts (SMT Type)

KITAGAWA INDUSTRIES America’s on-board contacts are all SMT (Surface Mount) type contacts, which give advantages of sophisticated structures and precision of work including:

KITAGAWA INDUSTRIES America carries a large selection of onboard contacts (OG) that are excellent grounding materials for reducing EMI noise at the board level.

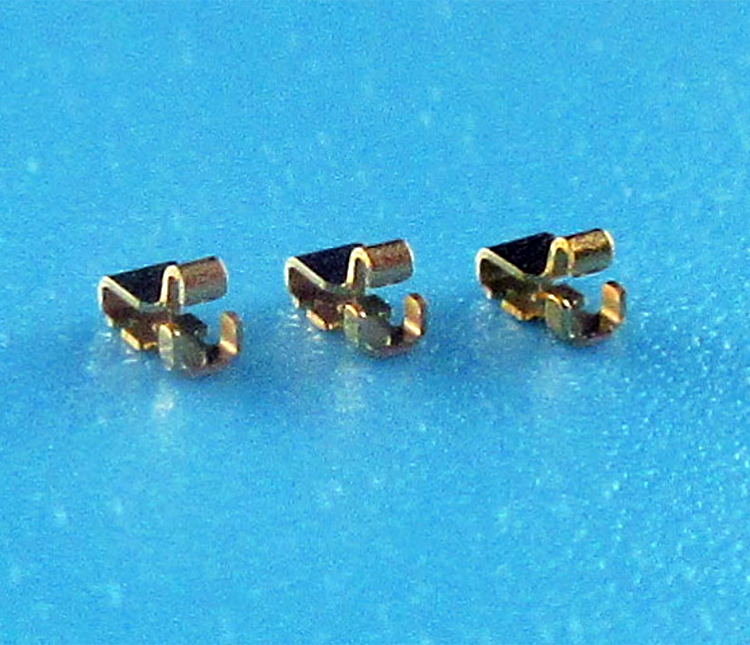

Tiny profile, board-level EMC grounding component. Compact design, great for space-conscious applications (such as smart, wearable devices).

On-board grounding component designed for small gaps. Low profile contact designed for space conscious applications.

Connecting a GND layer of PCB with multiple points on a chassis can be expected to suppress radiation noise. Can be used under high temperature at 150ºC.

SMT grounding contact for engine compartment PCB. Spring mechanism capable of withstanding 10 million deflections caused by engine vibration.

SMT-type EMC grounding contact for PCB’s in engine compartments. Unique dimple design allows for continued eletrical contact.

Compact cables clamps applicable to automated mounting on PC board. Board‐level wire management clamps. Available in side or top insertion.

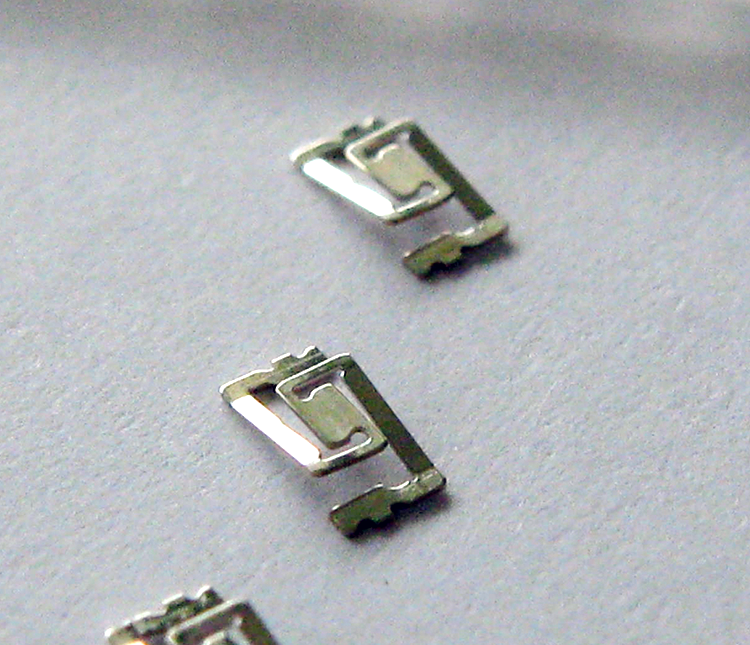

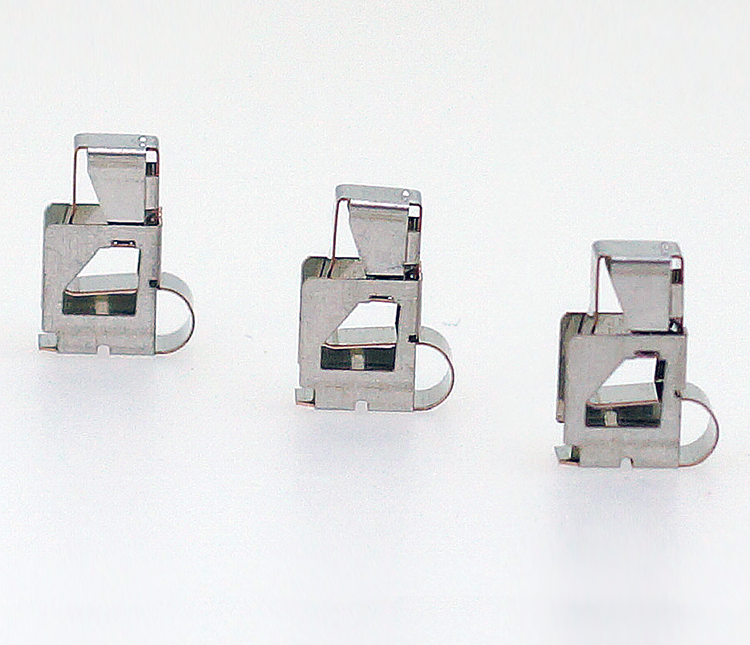

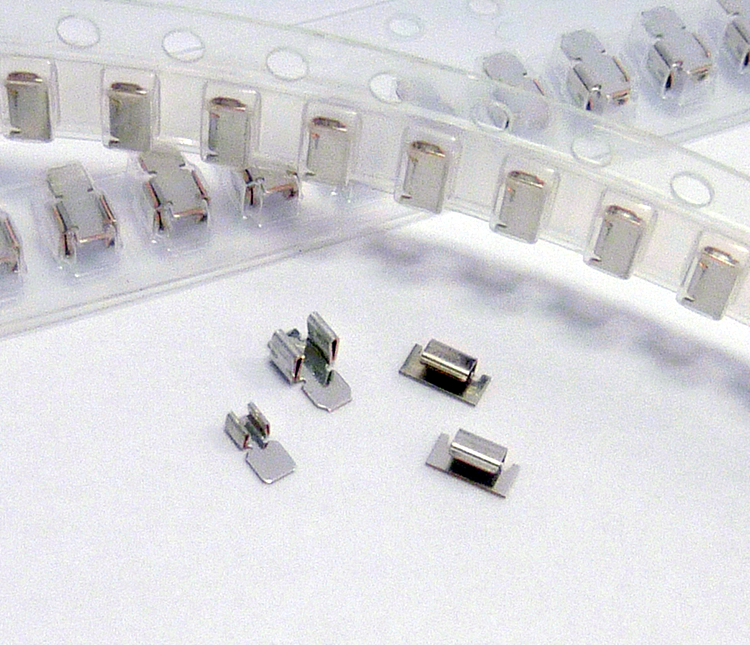

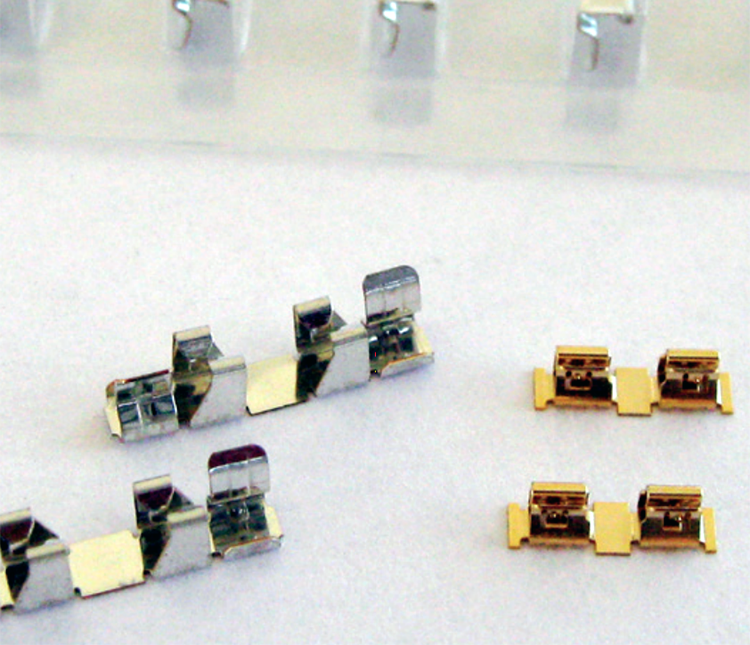

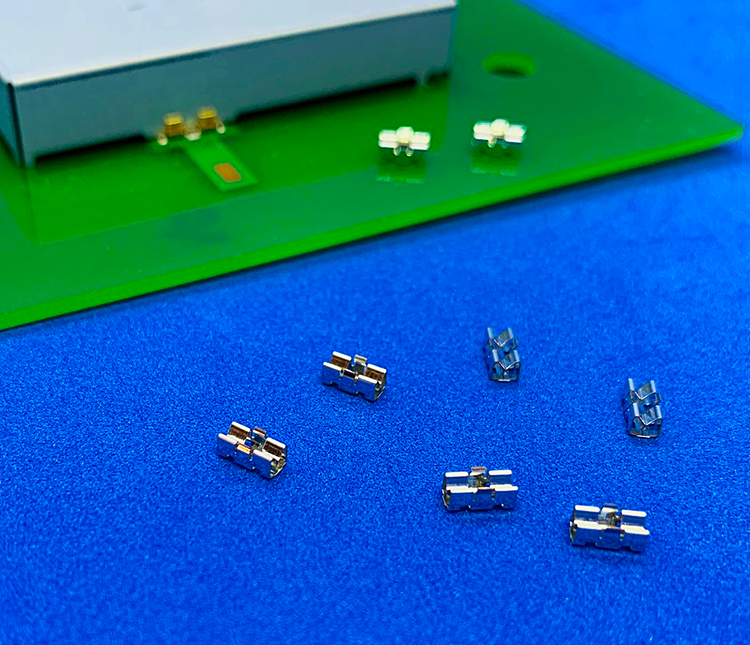

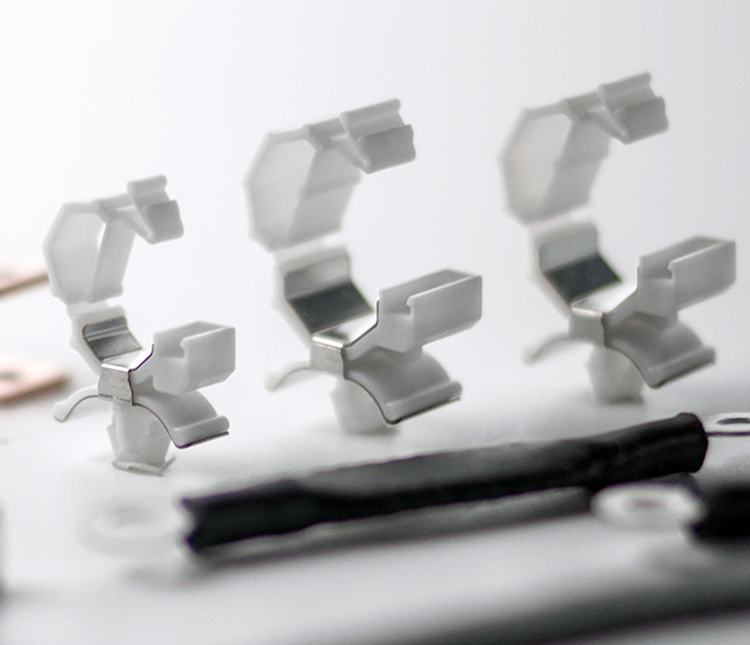

These are unique onboard contacts that act as both shielding can holders and rounding components. It can be snapped into the clips and taken off when needed.

Automated mounting applicable fixture “On-Board Clip” for shielding can. Multi-point GND is provided to shielding can and reinforced shielding performance.

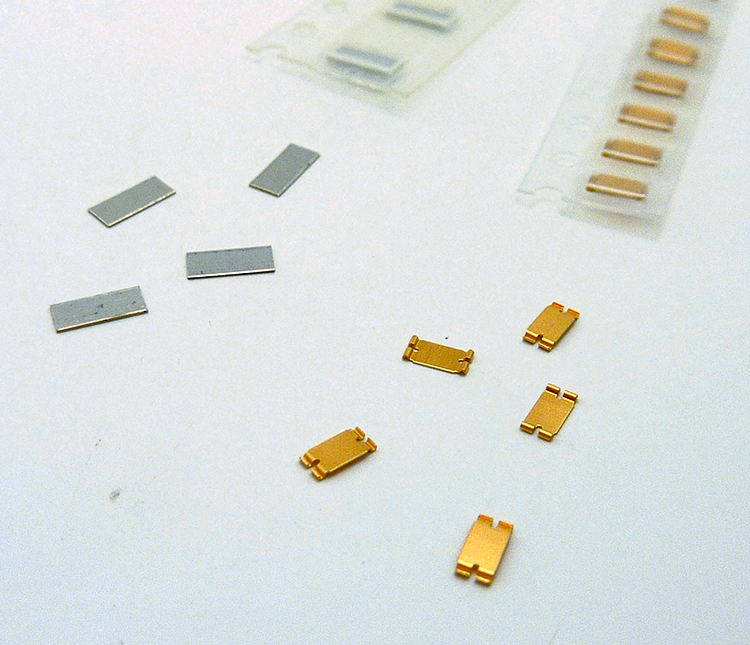

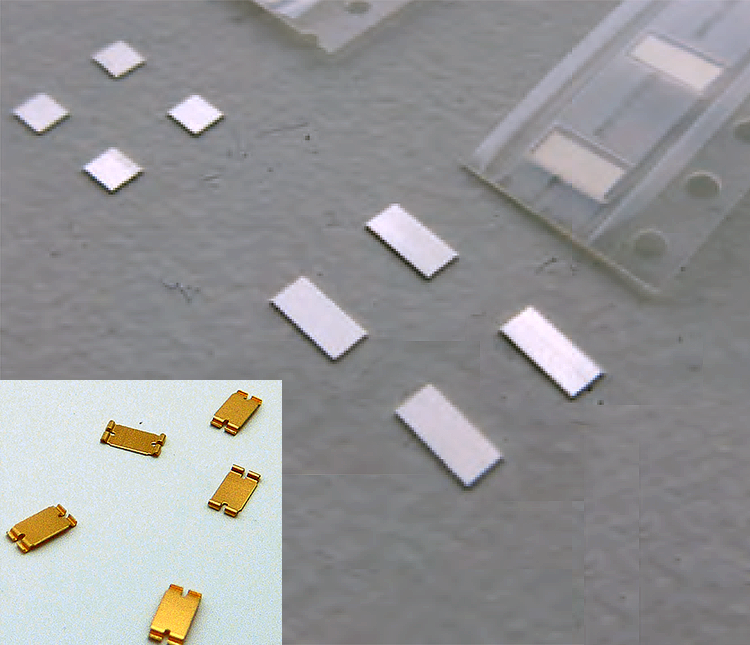

Eliminates problems with bad contact due to soldering flux. Ensures reliable, stable electrical contact for EMC grounding.

OGP solves contact failure problems caused by solder flux. Eliminates continuity failure caused by pattern scraping between a PCB and pogo pins and a PCB and a metal plate.

Side contacts for perpendicular grounding. Ideal for applications where standard grounding between parallel boards/chassis is not possible.

Side contacts for perpendicular grounding. Due to low profile design (2mm), it’s suitable for small electronic devices. Operating temperature -40ºC ~ 150ºC.

For reliable and stable electrical grounding when applied at screw holes. Helps to prevent EMC grounding reduction from loosened screws.

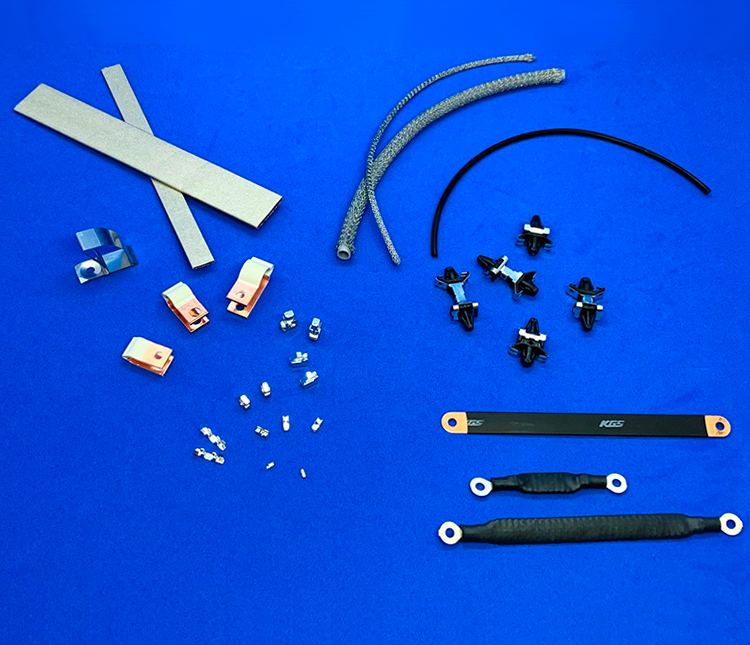

EMI Grounding Components

Well-designed grounding is an essential part of reducing EMI noise. KITAGAWA INDUSTRIES America can support all grounding needs with a variety of grounding components including grounding straps and plastic spacers with metalized areas. They come in a variety of sizes and shapes with different capabilities.

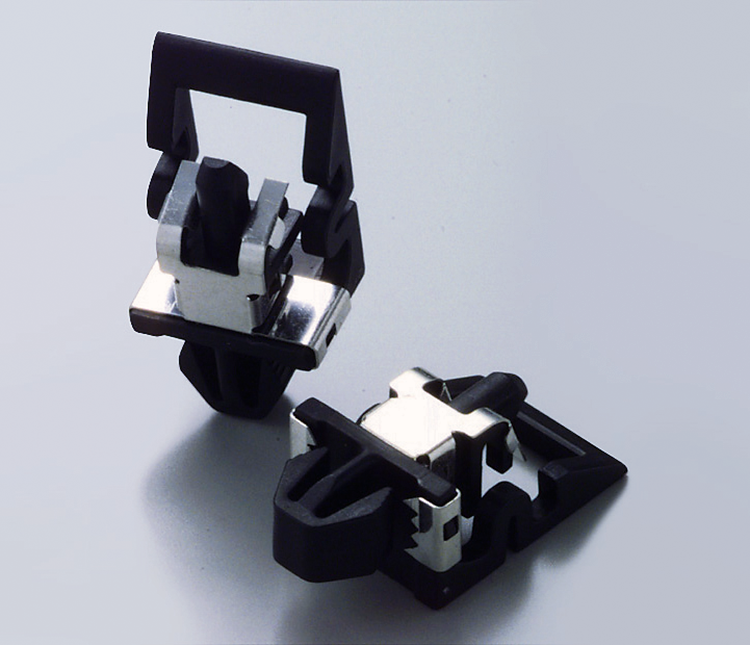

Suitable for contact in large clearance applications. Provides simultaneous fastening and grounding for coaxial and braid-shielded cables.

Combination of grounding and clamping with the FG series reduces the overall number of components in an application.

EMC grounding function is added to the spacer whose specialty lever system enables easy fixing and removal of PC board.

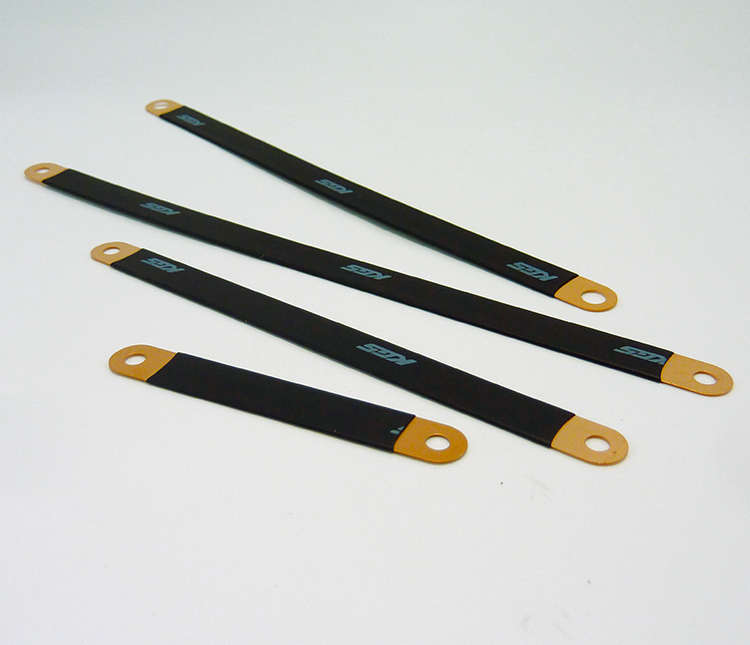

Low impedance, flat copper grounding strap for excellent EMC grounding. Lightweight, flexible straps allows for easy installation in tight spaces.

Metal mesh employed EMC grounding material. Extra-thin flexible wire mesh allows easy installation in narrow space configurations.

Molded black polycarbonate rail with spherical metal fingers provides simultaneous rigid guiding support and continuity of the ground draining circuit for the PC boards.

Screw free fixing spacer is combined with EMC grounding function. Light-weight PPE resin base provided with a tinned phosphor bronze conductive strip.

Suitable for contact in large clearance applications. Spring design maintains electrical contact after compression. Tall profile fits gap spaces from 10~20 mm.

Automotive Grade: On‐board Grounding Contact and Shield‐can Clip

Designed and tested to withstand conditions common in the auto industry. Automotive-grade means the parts are PPAP-ready (Level 3). Double-check the operating temperatures to ensure they meet your requirements. Please check the automotive-grade parts from the link below.

Connecting a GND layer of PCB with multiple points on a chassis can be expected to suppress radiation noise. Can be used under high temperature at 150ºC.

SMT grounding contact for engine compartment PCB. Spring mechanism capable of withstanding 10 million deflections caused by engine vibration.

SMT-type EMC grounding contact for PCB’s in engine compartments. Unique dimple design allows for continued eletrical contact.

Automated mounting applicable fixture “On-Board Clip” for shielding can. Multi-point GND is provided to shielding can and reinforced shielding performance.